Machining

CNC and manual machining

The whole workshop is enhanced by our excellent quality control department. Dimensional accuracy is assured with our three CMMs enabling a measuring range up to 2000mm in X axis, 1000mm in Y axis and 800mm in Z axis with Renishaw probes and controls. We have recently added a three-metre FARO arm for mobile CMM capability and we also have electronic height gauge and inspection-grade granite tables in temperature controlled environments.

This and our full range of conventional inspection equipment ensure comprehensive quality control of our machining work.

We supply fully machined castings and fabrications to defence, medical, marine, OE and automotive industries in the UK, Europe and North America. We are certified to ISO 9001, 14001 and 18001 with regular audit checks.

Our Kent-based site holds over twenty high-performance CNC machines from leading manufacturers such as Doosan and Heller and our whole automated section is supplemented by comprehensive conventional tools comprising horizontal boring, planing, universal milling, turning and drilling capabilities. This gives us the added flexibility for prototype, small batch and fixture works.

Current CNC plant list

Doosan HM1250 Horizontal Machining Centre

• Fanuc controller

• X-axis 2100 | Y-axis 1500 | Z-axis 1500

• Fitted with MP700 Spindle probe including Inspection Plus software

Heller MCI16 Horizontal Machining Centre – Two

• Siemens 840D control

• X-axis 800 | Y-axis 630 | Z-axis 630

• 160 tool carousel

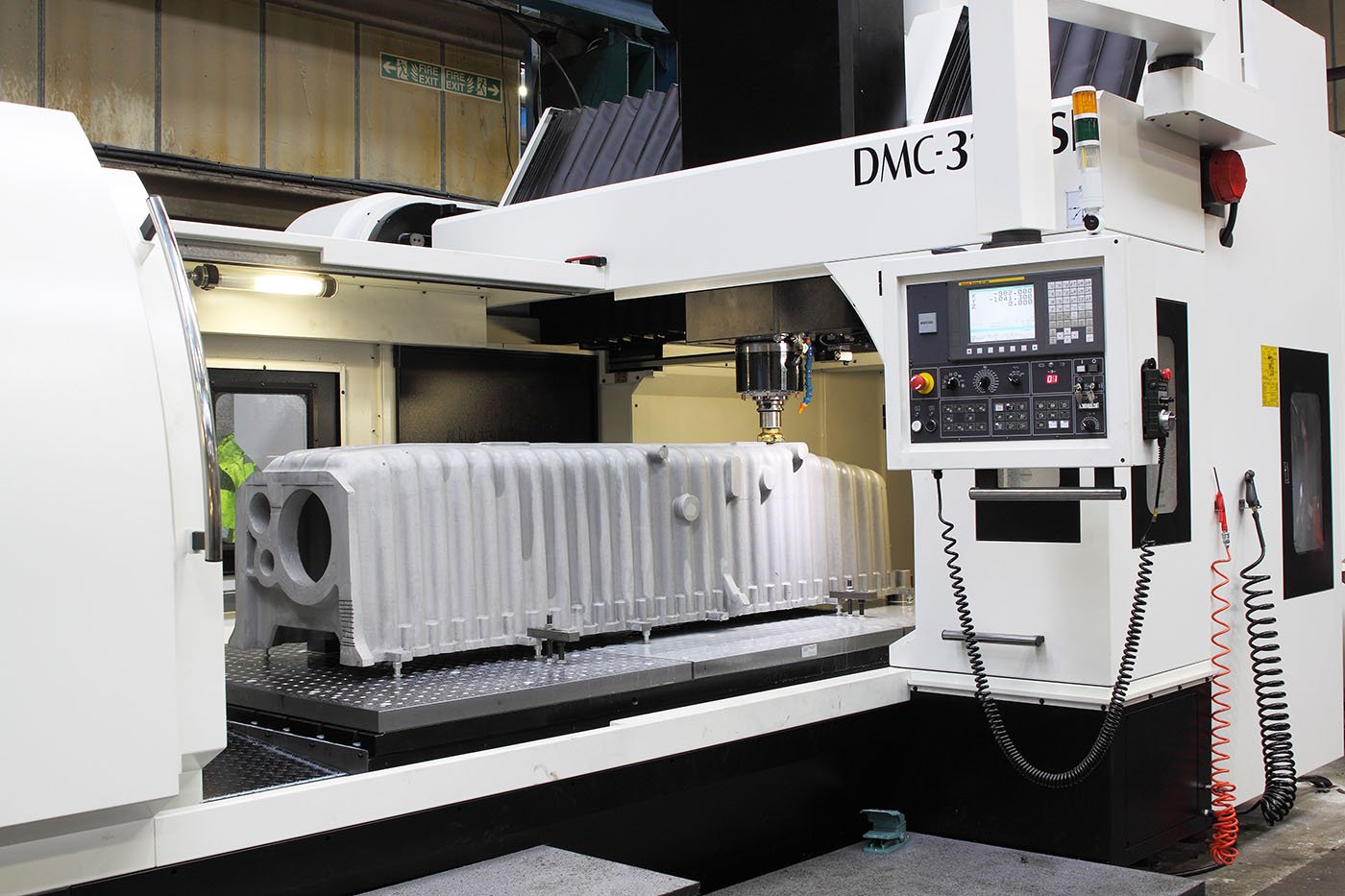

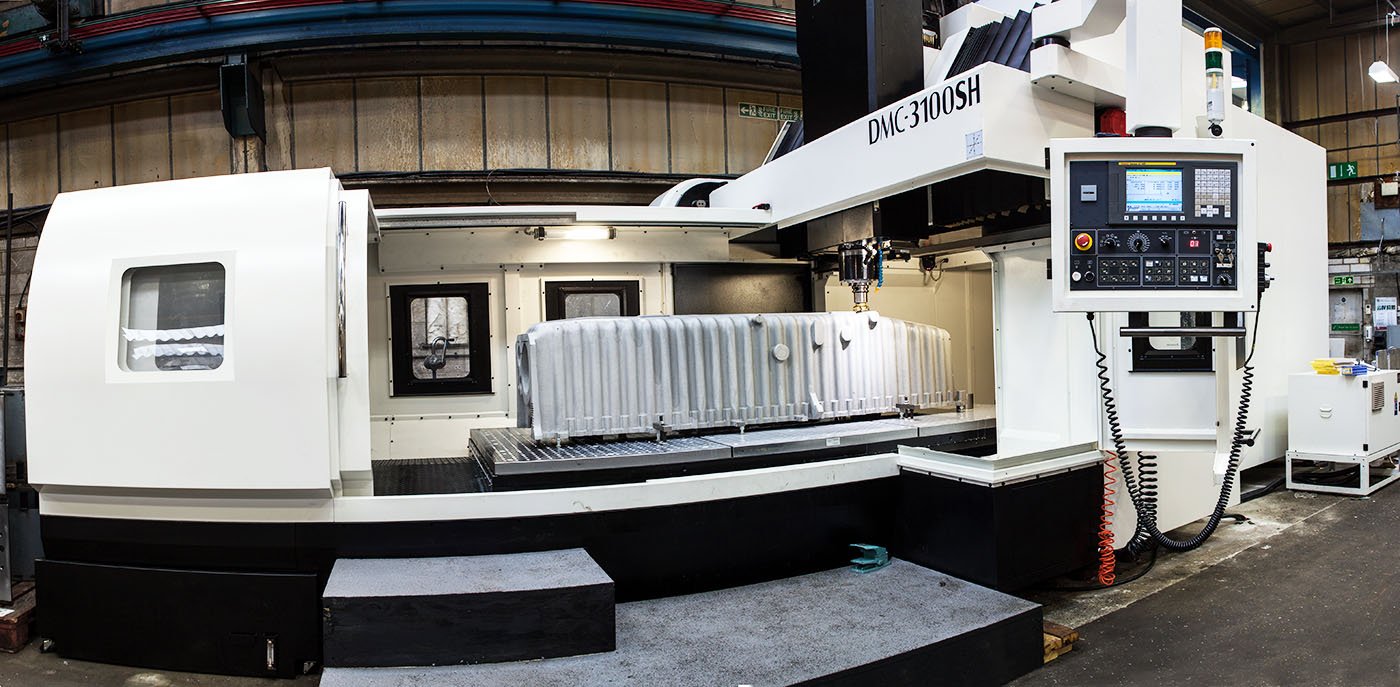

Johnford DMC3100SH Vertical Machining Centre

• Fanuc control

• X-axis 3100 | Y-axis 1778 | Z-axis 800

• Fitted with Renishaw TS 27R probe

Heller H4000 Horizontal Machining Centre – Two

• Siemens 840D control

• X-axis 800 | Y-axis 800 | Z-axis 800

• 1 with 160 tool carousel / 1 with 80 tool carousel

Webster & Bennett Titan Vertical Boring Mill

• Fanuc OT CNC control

• 47” chuck

• 1500 max swing diameter

Doosan DNM 500 II Vertical Machining Centre

• Fanuc CNC control

• X-axis 1020 | Y-axis 540 | Z-axis 510

• Spindle nose to table top 150 to 660

Dugard HD1886B HD Box Vertical Machining Centre

• Fanuc OiMF control

• X-axis 1800 | Y-axis 860 | Z-axis 700

• Fitted with Renishaw tool & spindle probing

• 40 tool carousel

Dugard HD1886B HD Box Vertical Machining Centre

• Fanuc OiMF control

• X-axis 1800 | Y-axis 860 | Z-axis 700

• Fitted with Renishaw tool & spindle probing

• 40 tool carousel

Mori-Seiki Junior Vertical Machining Centre

• X-axis 560 | Y-axis 410 | Z-axis 460

• Spindle nose to table top 150 to 610

• Spindle centre to column Front 680

Mori-Seiki AL-2 CNC Lathe

• Fanuc control

• Maximum diameter 250

• Length 533

• 8 station turret

Yang ML60A CNC Lathe

• Fanuc series O-T control

• Maximum diameter 550

• Length 1100

• Diameter through bore 100

• 8 station turret

Webster & Bennett Vertical Turning / Boring Mill

• 48” M series

• 64” actual maximum diameter

• 3.08 – 190 RPM

Doosan HP5100 II Horizontal Machining Centre

• Fanuc CNC control

• X-axis 850 | Y-axis 700 | Z-axis 750

• Pallet indexing 0.001 degree B-axis

Makino A100 E

• X-axis 3100 | Y-axis 1800 | Z-axis 1600

• RPM 12,000

Dugard Eagle HBM4 Horizontal Borer

• Fanuc 21i control

• X-axis 2200 | Y-axis 1600 | Z-axis 1600

• W-axis 550 quill with 360 degree B-axis

• Fitted with Renishaw spindle probing and Inspection Plus software

• 60 tool carousel

Toshiba BMC100 Horizontal Machining Centre

• 90 tool carousel

• Fanuc 600 control

• Twin pallet 1000 square

• X-axis 2000 | Y-axis 1250 | Z-axis 1000

• Fitted with Renishaw tool & spindle probing

ReTos W100A Horizontal Jig Borer

• Heidenhain control

• X-axis 1600 | Y-axis 1120 | Z-axis 1250

• W-axis 810 (quill)

• 360 degree ‘B’ axis

Dugard HD2210B HD Box Vertical Machining Centre

• Fanuc OiMF control

• X-axis 2200 | Y-axis 1000 | Z-axis 900

• Fitted with Renishaw tool & spindle probing

• 40 tool carousel

Manual and hand-machining

In addition to our CNC machines, we have a range of manual tools that offer precise and skilled finishing, cutting, milling or grinding by our experienced team.

Our fixed and mobile overhead cranes allow for safe maneuvering of pieces of all sizes and weights.

Multiple centre lathes at 254mm x 2000mm with a 610mm swing.

Three vertical milling machines at 1220mm x 305mm.

Jones & Shipman 540 surface grinder, working area of 600mm x 200mm.

A Startrite HB280A automatic metal cutting bandsaw that can accommodate pieces up to 280mm in diameter.

A wide assortment of pillar drills.

A Hydesco planer with working sizes up to 1825mm x 910mm.

A comprehensive range of assorted pedestal grinders.

Various overhead cranes, both fixed and mobile, with 3.2 tonnes of lifting capacity per single-use.