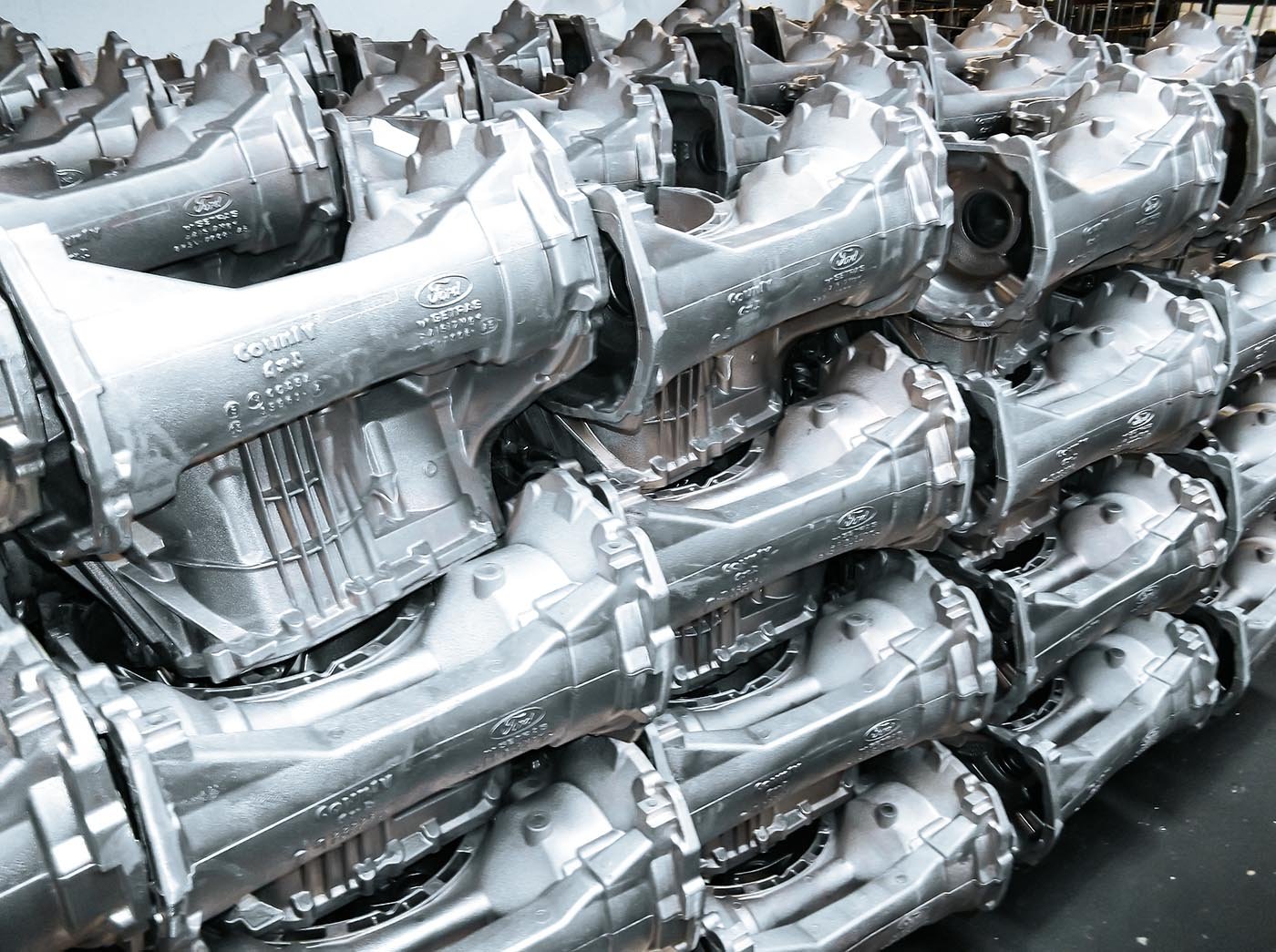

Castings - Al Cu Fe

Aluminium and copper-based bronze castings

We have been providing a comprehensive and industry-leading casting service from our own ferrous foundry since the 1960s. Patterns, castings and machining – all within one single workflow.

We produce a wide range of precision aluminium castings up to one tonne and copper-based bronze castings up to 120kg each. We are also experts in gravity die aluminium castings at up to 50kg and of truly exceptional integrity. Plus, we have a full range of heat treatment specifications.

We specialise in the casting and machining of large, high-complexity, sand castings that operate in demanding conditions such as high temperatures, immersions and completely pressurised systems.

Our facilities and procedures have developed to offer low-volume, multiple-batch and large-scale production quantities of components – all from one single enquiry and within one single location.

Grey and SG (ductile) iron castings

We began casting iron in our Kent-based foundry back in 1968, and we now deliver to customers across the world. We produce high-quality grey iron castings at grades 150 - 300 and weights of up to 380kg without issue.

Of special note is our ability to cast 400 / 18 LT SG iron, suitable for ‘low temperature’ applications of minus twenty degrees Celsius and minus forty degrees Celsius for railway applications. Additionally, we cast in a range of high silicon, low growth and special irons / alloys on request.

Our particular expertise is in complex core assembly work. All moulds are produced using air-set resin sand, ensuring the highest quality casting in soundness, dimensional accuracy and surface finish. Our iron foundry shares our adjoining non-ferrous foundry’s chemical and mechanical analysis, dye penetrant, ultrasonic inspection and pressure testing facilities.

All castings can be supplied machined and finished by our in-house machine shop or in raw form to suit your individual requirements.

Our team can also provide high quality Ni-resist (BS 3486), Ni-hard wear-resistant (BS 4844) and SiMo heat-resistant iron alloys to exceptional quality and competitive pricing.